Delta Castle

Problem:

- Double pick-up device at input tray.

- Castle detect maximum tray reach.

- Upper VAT latch could not retract.

- Testsite could not pick units from boat.

- Encounter TS pusher unable to extend.

- Input VAT sense 1 tray more than actual.

- Marvell E1146: Chuck stuck at dockplate.

- Z-HEAD (z-tips) is not aligned.

- LN2 leaking at junction box.

- Pickup error from PNP B3.

- H02-CAST hang-up upon running production.

- Delta Castle motor torque reversed.

Date: 11/11/05

Problem:

Delta Castle motor torque reversed.

Troubleshooting route:

- Motor is free when torque is ON, and motor is lock when torque is OFF.

- Get assistance from Allan from Equipment for troubleshooting.

- Reboot handler, same.

- Check Power Supply voltage, all OK.

Solution:

- Go to Control Screen -> System Group.

- Select Group Screen then highlight Default followed by Activate.

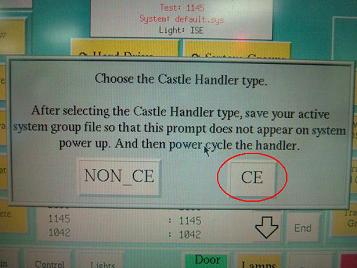

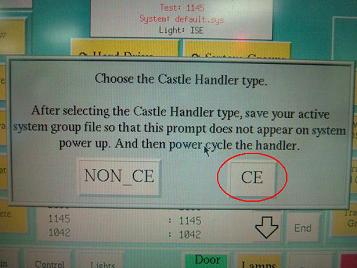

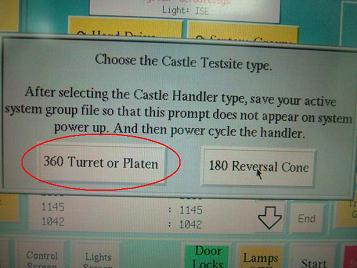

- Handler will prompt for 2 questions, refer to attachment.

- Select CE for first question.

First question - CE

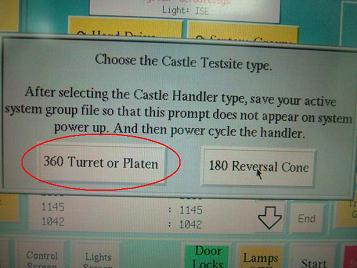

- Select 360 Turret or Platen for second question.

Second question - 360 Turret or Platen

- After that select back the device for setup followed by Activate.

- Reboot handler, done.

Conclusion:

CE and NON_CE mode causing the torque status reversed.

Remarks:

N/A.

Done by:

- Allan Choi (Test Equipment Senior Associate Engineer)

- Lim Chang Fei (PM Group)

Date: 11/21/05

Problem:

H02-CAST hang-up upon running production.

Troubleshooting route:

- Run dry cycle mode, handler OK.

- Change to Normal Mode, handler hang when PnP attempt to pick unit from Input VAT.

- Try other Package file, handler OK.

- Switch back 1042 package file, notice that 6 out of 8 pick-up arm was disable.

- Do some experiment, once too many arm was disable, handler will hang upon Normal Mode selected.

Solution:

- Attempt to enable all pick-up arm, however, the remaining 6 pick-up arm was not functioning.

- Need to fix the arm in order to run production.

- Trace the air supply, notice once the join on the air exchange was removed, all the 8 arms movement was fine.

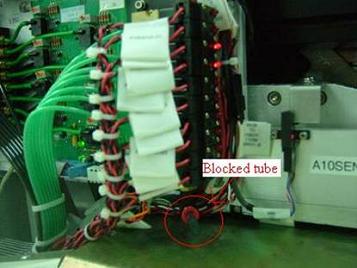

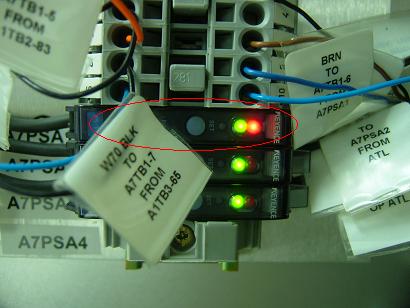

Air exchange point for the pick-up arm movement

- Try to align the point, 5 out of 8 arm was fixed.

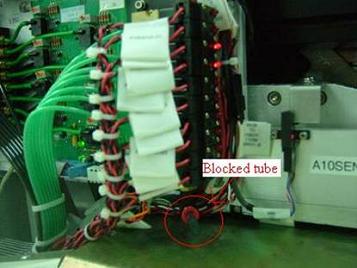

- Trace the tubing till the cylinder, notice an exhaust tubing was blocked.

- Remove the blocked item, all 8 arms working fine.

- Cycle with 2 trays of unit, OK.

Blocked tube

Conclusion:

Misalignment of air exchange point and block on exhaust tubing causing the air holding the arm unable to be release upon air pressure cut-off.

Remarks:

N/A.

Done by:

Lim Chang Fei (PM Group)

Date: 08/30/05

Problem:

Pickup error from PNP B3.

Troubleshooting route & Solution:

- Visual inspected v-head and discovered B3 pickup head loose.

- Tried tightened it but still leaving a gap in between pnp head and B3 head.

- Moreover head is still loose.

- Original screw for v head tip was a half thread type but this particular one was using a full 4/40 screw.

- Reason was that the pnp head tip screw thread had worn out.

- Had confirmed with other v-head tip and still having diffculty in tightening it.

- Tried filing the full thread screw to half thread and able to tightened it.

- Monitor upon production run and no similar fault on pickup issue found.

Conclusion:

Screwthread on the PNP head B3.

Remarks:

N/A.

Done by:

Chua Choon Boon, Desmond (B-Shift Shift Leader, Test Manufacturing Senior Associate Engineer)

Date: 07/26/05

Problem:

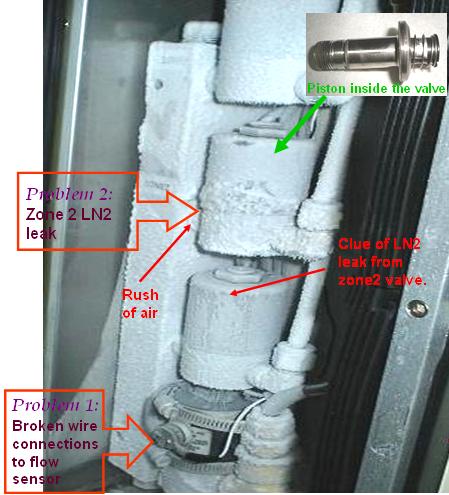

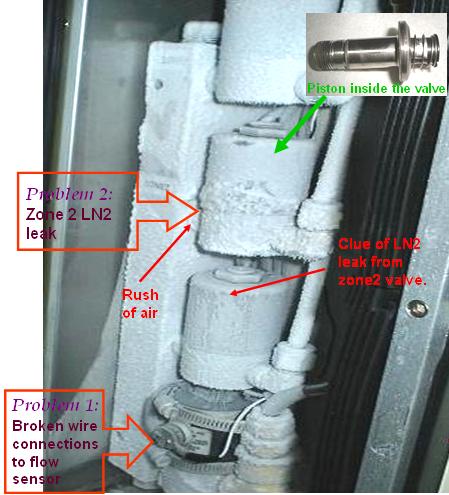

LN2 leaking at junction box.

Troubleshooting route & Solution:

- The valves junction inside the chamber were checked and noticed that the wires connected to the flow sensor of the main valve is cut.

- Resoldered the wires to the sensor and fixed it to the main valve.

- Enabled the Cold temperature at -40C without opening the valve of the LN2 tank.

- The valves at junction were working fine by way of the ticking sound.

- Opened the valve of the LN2 tank to let the liquid flow.

- Felt the surrounding of the four valves for any abnormality.

- Noticed that there is a rush of air within Zone #2.

- Aligned and tighten the contactor of the valve at Zone #2, rush of air diminished.

- At -10C temperature, LN2 started to flow out of the Zone #2 valve. Defrosted and heated the junction box.

- Removed the contactor of Zone #2 valve and noticed the piston is loose, tighten it.

- Also checked Zone #1 valve and tighten the piston since it is loose.

- Enabled the cold temperature again to -40C and only a slight leak at Zone #1 valve was seen and diminished when the temperature is stabilized at -40C.

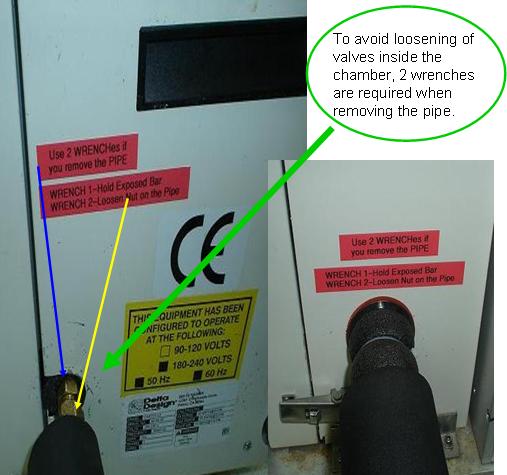

LN2 Junction Box

Conclusion:

Leakage seen was due to broken wire for the sensor of the main valve and loose piston inside the valve.

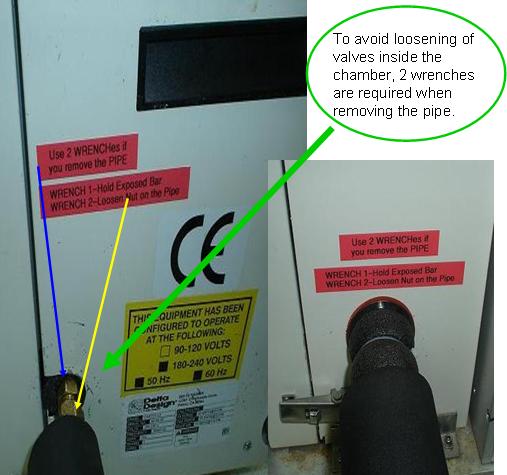

Remarks:

- Whenever you need to remove the LN2 pipe connected to the handler, kindly use 2 wrenches to avoid loosening the valve connection inside the junction box.

Removal of hose

Done by:

Ferdie Catahay Aquino (Other Tester Module Leader, Line Engineer)

Date: 07/26/05

Problem:

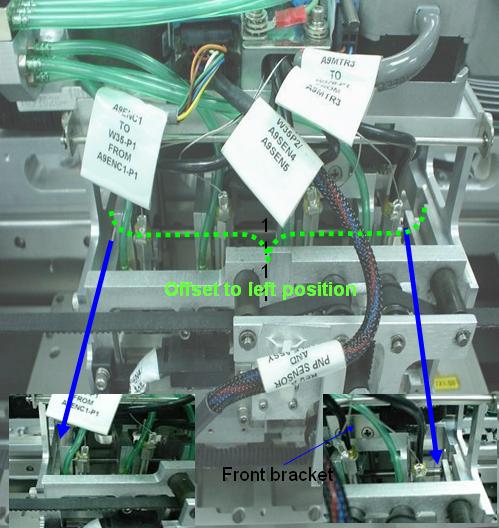

Z-HEAD (z-tips) is not aligned.

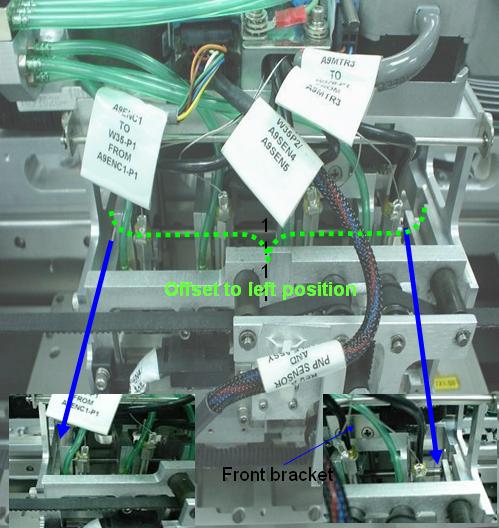

Troubleshooting route & Solution:

- Removed the suction cups from the Z-tips.

- Moved the Z-HEAD assembly manually to align the pitch with respect to the center of the boat.

- Able to center but the Z-HEAD assembly is already hitting hard stop at left position.

- The boat center position value was -0.07inches and when saved an error is shown that the data cannot be saved.

- Verify the position of the Z-HEAD assembly with another handler. Noticed that it is centered.

- Checked for any obstruction. No obstruction found.

- Loosen the screws of the brackets that attached the Z-HEAD assembly to the belt. The Z-tips can moved freely.

- Aligned the Z-tips pitch with respect to the boat center and was able to save the 0.04 inches position.

- Tightened the screws and continue teaching for pitch tray center, X-center position for boat and tray.

- Verify the alignment with dummy units and so far okay with the 8 z-tips.

Castle Pick & Place Module

Conclusion:

Z-HEAD alignment is offset.

Remarks:

- Take note of the front bracket position, if moved too much to the right it will caused the pitch home position to be stalled.

- If the pitch tray position cannot be achieved, need to lower the Z-position of the Z-HEAD prior to homing of pitch tray postion.

Done by:

Ferdie Catahay Aquino (Other Tester Module Leader, Line Engineer)

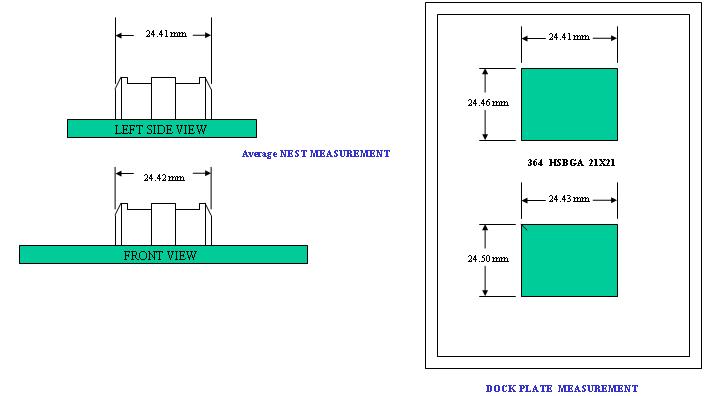

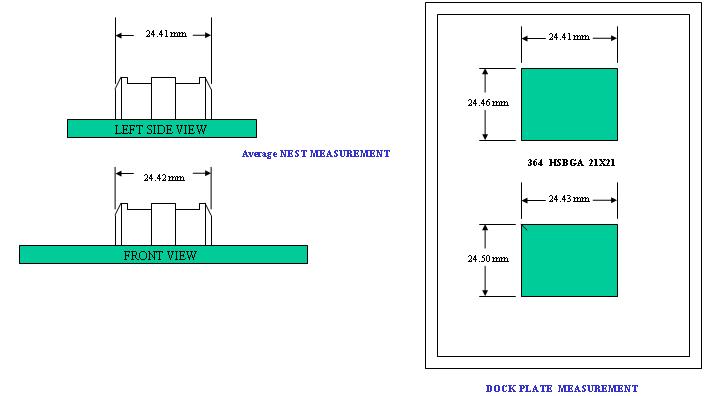

Date: 03/07/05

Problem:

Marvell E1146: Chuck stuck at dockplate.

Troubleshooting route:

- Encountered frequent jamming at contact site, especially at hot temp.

- Found that the nest and dockplate opening were almost the same measurement.

Nest & Dockplate measurement

Solution:

- Sent dockplate to vendor for modification of the dockplate.

Conclusion:

Too little play between nest & dockplate causing chuck easily stucked.

Remarks:

N/A.

Done by:

Salvador Supena Cuate, Buddy (LTX CX Module Leader, Senior Line Engineer)

Date: 01/26/05

Problem: Input VAT sense 1 tray more than actual.

Troubleshooting route:

- Reinitialize handler, problem exist.

- Remove all the tray and reinitialize handler, detected 1 tray where actual fact there is no tray.

- Power down handler & power up, initialize handler, problem exist.

- Suspect VAT teaching is out.

Solution:

- Initialize BBU, Control SCreen -> Boat Xport Screen -> Initialize BBU -> VAT.

- Perform teaching for Upper & Lower VAT Water Level.

Upper VAT Water Level teaching

- Control Screen -> Reinit System.

- STOP handler when Upper VAT latch lifting first VAT.

for Video Clip

for Video Clip

First VAT reaching Water Level

- Control Screen -> Vertical Auto Tray -> Motor Screen -> Diags OFF.

- Select Upper. Press "-" then slowly lower the VAT till lower than the Water Level Sensor and the sensor is not cut.

Water Level Sensor Not Cut

- Press "+" then slowly lift the VAT till the Water Level Sensor is cut.

Water Level Sensor is Cut

- Press Learn -> Water Level -> Jog -> Diags ON.

Lower VAT Water Level teaching

- Control Screen -> Reinit System.

- STOP handler when Lower VAT (Input VAT) reaching Water Level.

for Video Clip

for Video Clip

Lower VAT reaching Water Level

- Control Screen -> Vertical Auto Tray -> Motor Screen -> Diags OFF.

- Select Lower. Press "-" then slowly lower the VAT till lower than the Water Level Sensor and the sensor is not cut.

- Press "+" then slowly lift the VAT till the Water Level Sensor is cut.

- Press Learn -> Water Level -> Jog -> Diags ON.

- Finally reinitialize whole handler.

Conclusion:

VAT teaching is out causing error in tray calculation.

Remarks:

N/A.

Done by: Lim Chang Fei (PM Group)

Date: 01/26/05

Problem: Encounter TS pusher unable to extend.

Troubleshooting route:

- Go to Diag ON mode and retract pusher, extend pusher again.

- Encounter Torque error.

- Open side door cover and check the pusher.

- Notice that there is a NEST stuck at the Testsite, Site A1.

Nest stuck at testsite

- The picker is without the nest, affected part is from CHUCK #2.

Picker without nest

- Undock and pull the nest out.

- Tried manually fitting the nest into the dockplate, very smooth.

- Take the whole Chuck #2 out, noticed that the screw for the the nest are still attached onto the chuck.

- The whole shim-liked parts (which holds the nest and the chuck together) are stuck onto the screw.

Solution:

- Replace another nest from H/W control.

- Manually fitting the chuck onto the dockplate, OK.

- Check chuck assembly, no dented parts.

Conclusion:

Spoilt nest causing pick-up error at testsite.

Remarks:

No more nest in H/W control. 1 damaged and 1 worn out.

Done by: Chua Gee Wee, Raymond (C-Shift Shift Leader, Test Manufacturing Senior Associate Engineer)

Date: 01/22/05

Problem: Testsite could not pick units from boat.

Troubleshooting route & Solution:

- Checked chucks at testsite, nest & guide pins OK.

- Retry pick-up, noticed that chucks tend to lift the boats up on picking.

- Adjusted centre positions of Indexers 3 and 4 from 0.537 to 0.532 and 0.540 to 0.545 respectively.

Conclusion:

Indexer 3 & 4 teaching teaching is out.

Remarks:

Ongoing monitoring..

Done by: Chew Thaddaeus, Kyle (D-Shift, Test Manufacturing Associate Engineer)

Date: 01/22/05

Problem: Upper VAT latch could not retract.

Troubleshooting route & Solution:

- Re-initialize handler, latch would not retract.

- Reload handler system file, problem still persist.

- Perform Upper and Lower VAT reteaching, latch retracted but handler sensed 2 trays in every platform when there was none.

- Re-Taught VAT, re-iniatlised handler, VAT errors solved.

Conclusion:

VAT teaching is out.

Remarks:

N/A.

Done by: Chew Thaddaeus, Kyle (D-Shift, Test Manufacturing Associate Engineer)

Date: 10/13/04

Problem: Double pick-up device at input tray.

Troubleshooting route:

- Remove all device in handler.

- Reinitialize whole handler.

- Manually insert 4 units at boat near Indexer 1.

- Set handler mode to Flush & observe situation.

- Observe that same pick-up arm pick the first unit pick for second unit.

Solution:

- Open right side door of castle & slightly adjust vacuum

sensor, OK.

- Insert unit at boat near Indexer 1, redo Flush Mode, OK.

- Run offline cycle mode, OK.

- Release to production.

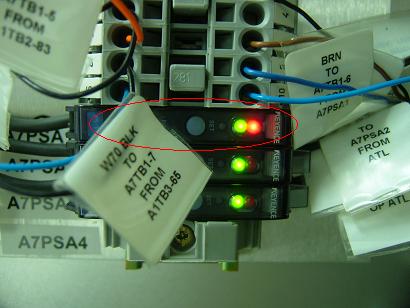

Vacuum sensor board.

Conclusion:

Vacuum sensor not sensitive.

Remarks: N/A.

Done by: Lim Chang Fei (PM Group)

Date: 10/13/04

Problem: Castle detect maximum tray reach.

Troubleshooting route:

- Reinitialize whole handler, castle prompt maximum tray reach,

initialize failed.

Solution:

- Check tray sensor of handler.

Tray sensor

- Found that sensor always sense block.

- Check sensor connection, found 1 of the sensor is loose.

Loose sensor

- Slightly tighten the sensor, sensor sense unblock.

- Initialize whole handler, successful.

Conclusion: Loose sensor block the sensitivity.

Remarks: N/A

Done by: Lim Chang Fei (PM Group)